The Titanic, one of the most iconic ships in history, continues to captivate the world with its tragic yet remarkable story. Known as the "unsinkable ship," the Titanic was not only a marvel of engineering but also a symbol of human ambition and innovation. The origins of this legendary vessel trace back to the bustling shipyards of Belfast, Ireland, where the ship was meticulously crafted by some of the finest engineers and laborers of the early 20th century. The construction of the Titanic marked a turning point in maritime history, showcasing the height of industrial prowess during the Edwardian era. Today, the legacy of the Titanic continues to inspire awe, and understanding where Titanic was made provides a deeper appreciation for the craftsmanship and dedication that went into building this legendary ship.

As we delve into the story of where Titanic was made, we uncover the intricate details of its construction, the people involved, and the challenges faced during its creation. The Harland and Wolff shipyard in Belfast played a pivotal role in the Titanic's construction, employing thousands of workers who contributed their skills and expertise to bring this massive vessel to life. The shipyard's reputation for quality and innovation made it the perfect location for constructing such a grand ship. The Titanic's construction was a monumental task, requiring state-of-the-art technology and an unparalleled level of precision. From the keel-laying to the final fitting-out, every step in the process was meticulously planned and executed, ensuring that the Titanic would live up to its reputation as the most luxurious and advanced ocean liner of its time.

While the Titanic's tragic fate has overshadowed its achievements, the story of where Titanic was made remains a testament to human ingenuity and perseverance. The ship's construction site in Belfast has since become a tourist attraction, drawing visitors from around the world who wish to learn more about the Titanic's history and its impact on maritime engineering. Through this article, we aim to explore the fascinating journey of the Titanic's creation, uncovering the stories of the people who built it, the challenges they faced, and the lasting legacy of this legendary vessel. Join us as we embark on a journey to uncover the origins of the Titanic and the remarkable story behind its construction.

Read also:How To Choose The Best Cheap Plastic Plant Pots For Your Garden

Table of Contents

- Where Titanic Was Made: The Birthplace of a Legend

- Why Was the Titanic Built in Belfast?

- How Long Did It Take to Build the Titanic?

- Who Built the Titanic?

- What Were the Challenges in Building the Titanic?

- Exploring the Harland and Wolff Shipyard

- What Innovations Were Introduced in Titanic's Construction?

- The Titanic's Legacy: Why Does It Matter?

Where Titanic Was Made: The Birthplace of a Legend

The Titanic's construction began in the bustling shipyards of Belfast, Ireland, at the Harland and Wolff shipyard. This historic shipyard, established in 1861, was renowned for its exceptional craftsmanship and innovative approach to shipbuilding. The decision to construct the Titanic in Belfast was not arbitrary; it was a strategic choice based on the shipyard's reputation for quality and its proximity to key resources. The Harland and Wolff shipyard was perfectly equipped to handle the massive undertaking of building the Titanic, with facilities capable of accommodating the ship's enormous size and intricate design.

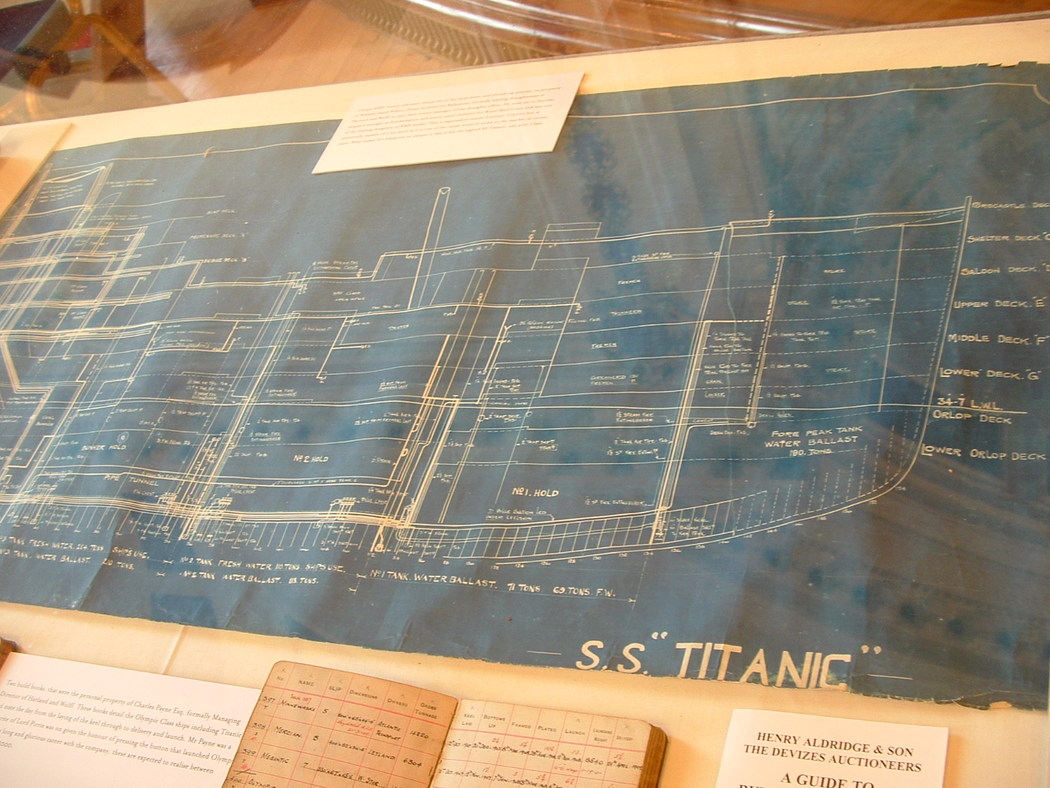

The Titanic's construction began in March 1909 with the laying of its keel. Over the next two years, thousands of skilled workers poured their efforts into crafting the ship, transforming raw materials into a masterpiece of engineering. The shipyard employed over 15,000 workers at its peak, each contributing their unique skills to the project. The construction process was divided into several stages, including the fabrication of the hull, the installation of the engines, and the fitting-out of the ship's luxurious interiors. Every aspect of the Titanic's construction was meticulously planned, ensuring that the ship would meet the highest standards of safety, comfort, and elegance.

Why Was the Titanic Built in Belfast?

Belfast was chosen as the location for the Titanic's construction due to its strategic advantages and the expertise of its workforce. The Harland and Wolff shipyard had a long-standing reputation for building some of the world's finest ships, making it the ideal choice for such an ambitious project. The shipyard's proximity to natural resources, including iron ore and coal, further solidified its position as the perfect location for constructing the Titanic. Additionally, the shipyard's facilities were specifically designed to accommodate large-scale projects, with dry docks and slipways capable of handling ships of the Titanic's size.

The decision to build the Titanic in Belfast was also influenced by the city's thriving industrial economy. During the early 20th century, Belfast was one of the most industrialized cities in the world, with a workforce skilled in a variety of trades. The shipyard's workers were renowned for their craftsmanship, and their expertise was instrumental in the Titanic's construction. The combination of skilled labor, state-of-the-art facilities, and access to resources made Belfast the perfect location for building the Titanic, ensuring that the ship would be constructed to the highest standards of quality and innovation.

How Long Did It Take to Build the Titanic?

The construction of the Titanic was a monumental task that spanned over two and a half years. The ship's construction began in March 1909 with the laying of the keel and concluded in April 1912 with its ill-fated maiden voyage. The entire process was divided into several stages, each requiring a significant amount of time and effort. The initial stage involved the fabrication of the hull, which took approximately 26 months to complete. Following this, the ship's engines and boilers were installed, a process that required an additional six months. Finally, the ship underwent a fitting-out period, during which its luxurious interiors were completed, taking another six months to finish.

Throughout the construction process, thousands of workers were involved in every aspect of the Titanic's creation. The shipyard operated around the clock, with workers laboring tirelessly to meet deadlines and ensure the ship's quality. Despite the challenges faced during construction, the Titanic was completed on schedule, showcasing the dedication and expertise of the workers involved. The entire construction process was a testament to human ingenuity and perseverance, setting a new standard for shipbuilding during the Edwardian era.

Read also:Ultimate Guide How To Get A Stain Out Of White Shirt With Proven Methods

Who Built the Titanic?

The Titanic was built by the Harland and Wolff shipyard in Belfast, under the supervision of the White Star Line. The shipyard's workforce consisted of over 15,000 skilled laborers, each contributing their unique expertise to the project. Among these workers were shipwrights, engineers, plumbers, electricians, and painters, all working together to bring the Titanic to life. The construction process was overseen by a team of experienced supervisors and engineers, including Thomas Andrews, the ship's designer, and Lord Pirrie, the managing director of Harland and Wolff.

The workers at the Harland and Wolff shipyard faced numerous challenges during the Titanic's construction, including harsh working conditions and the need for precision in every aspect of the build. Despite these challenges, the workers remained committed to their task, driven by a shared sense of pride and purpose. Their efforts resulted in the creation of a ship that was not only the largest and most luxurious of its time but also a testament to the skills and dedication of the people who built it. The Titanic's construction was a collaborative effort, showcasing the best of human ingenuity and craftsmanship.

What Were the Challenges in Building the Titanic?

Building the Titanic presented numerous challenges, both technical and logistical. One of the primary challenges was the sheer size of the ship, which required the development of new tools and techniques to handle its massive components. The ship's hull, for example, was constructed from over 2,000 steel plates, each weighing several tons, requiring specialized cranes and equipment to lift and position them. Additionally, the ship's engines and boilers were among the largest ever built, necessitating the creation of new methods for their installation and operation.

Another significant challenge was ensuring the safety and stability of the Titanic. Engineers had to carefully calculate the ship's weight distribution and buoyancy to ensure that it could safely navigate the ocean. This involved extensive testing and analysis, as well as the incorporation of advanced safety features, such as watertight compartments and a double hull. Despite these efforts, the Titanic's design ultimately proved insufficient to prevent its tragic sinking, highlighting the importance of continuous innovation and improvement in shipbuilding.

Exploring the Harland and Wolff Shipyard

The Harland and Wolff shipyard in Belfast was the epicenter of the Titanic's construction, serving as the heart of the operation. Established in 1861, the shipyard had a long history of building some of the world's finest ships, earning a reputation for quality and innovation. The shipyard's facilities were specifically designed to accommodate large-scale projects, with dry docks and slipways capable of handling ships of the Titanic's size. The shipyard's workforce was renowned for its expertise, with thousands of skilled laborers contributing their unique skills to the Titanic's construction.

Today, the Harland and Wolff shipyard remains a symbol of Belfast's industrial heritage and the Titanic's legacy. The shipyard has been partially repurposed as a tourist attraction, offering visitors a glimpse into the world of shipbuilding during the early 20th century. The Titanic Belfast museum, located near the shipyard, provides an immersive experience that brings the story of the Titanic to life, showcasing the ship's construction, its tragic voyage, and its lasting impact on maritime history. Through exhibits, interactive displays, and guided tours, visitors can gain a deeper understanding of the Titanic's origins and the people who built it.

What Innovations Were Introduced in Titanic's Construction?

The Titanic's construction was marked by several groundbreaking innovations that set it apart from other ships of its time. One of the most significant innovations was the use of advanced steel construction techniques, which allowed for the creation of a ship that was both larger and stronger than any that had come before it. The Titanic's hull was constructed from over 2,000 steel plates, each carefully riveted together to form a seamless structure. This innovative approach to construction not only increased the ship's strength but also improved its durability and resistance to the elements.

Another key innovation was the incorporation of advanced safety features, including watertight compartments and a double hull. These features were designed to enhance the ship's safety and stability, allowing it to withstand even the most challenging conditions at sea. Additionally, the Titanic was equipped with state-of-the-art engines and boilers, capable of generating enough power to propel the ship at speeds of up to 24 knots. These innovations, combined with the ship's luxurious interiors and cutting-edge technology, made the Titanic a marvel of its time, setting a new standard for ocean liners and influencing the future of shipbuilding.

The Titanic's Legacy: Why Does It Matter?

The Titanic's legacy extends far beyond its tragic sinking, serving as a powerful reminder of human ambition, innovation, and resilience. The story of where Titanic was made provides valuable insights into the history of shipbuilding and the impact of industrialization on society. The Titanic's construction was a testament to the skills and dedication of the people who built it, showcasing the best of human ingenuity and craftsmanship. Despite its tragic fate, the Titanic continues to inspire awe and admiration, serving as a symbol of human achievement and perseverance.

Today, the Titanic's legacy is celebrated through museums, exhibits, and cultural events around the world. The Titanic Belfast museum, located near the shipyard where the Titanic was built, offers visitors a unique opportunity to explore the ship's history and its impact on maritime engineering. Through exhibits, interactive displays, and guided tours, the museum brings the story of the Titanic to life, highlighting the achievements of its builders and the challenges they faced. The Titanic's legacy serves as a reminder of the importance of innovation, safety, and quality in all aspects of human endeavor, inspiring future generations to strive for excellence and push the boundaries of what is possible.

FAQs

How many people worked on the Titanic's construction?

Over 15,000 skilled laborers worked on the Titanic's construction, each contributing their unique expertise to the project. The workforce included shipwrights, engineers, plumbers, electricians, and painters, among others, all working together to bring the Titanic to life.

What was the Titanic's top speed?

The Titanic was capable of reaching speeds of up to 24 knots, thanks to its state-of-the-art engines and boilers. This made it one of the fastest ocean liners of its time, setting a new standard for speed and efficiency in maritime travel.

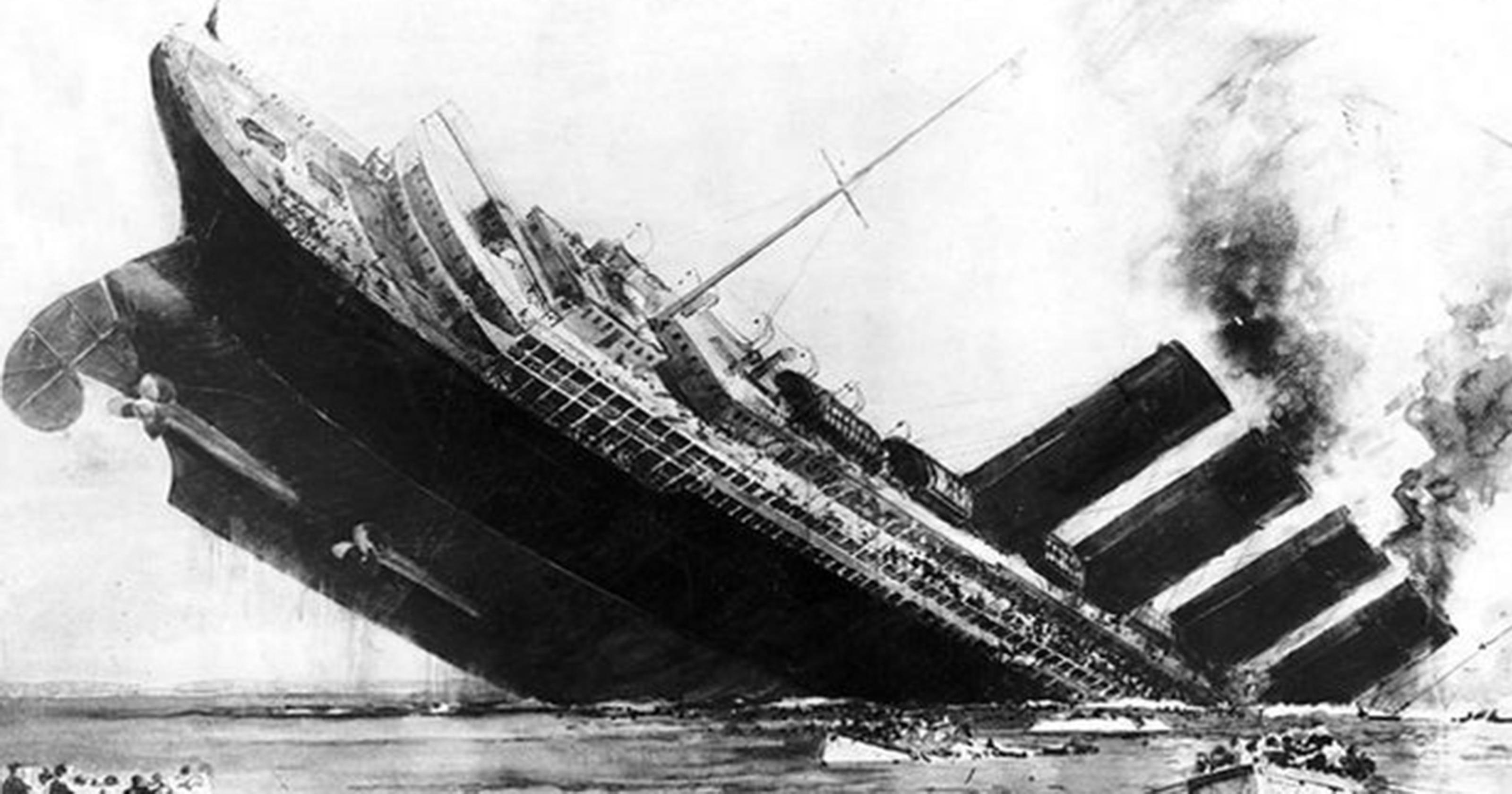

Why did the Titanic sink?

The Titanic sank after striking an iceberg on its maiden voyage in April 1912. The impact caused significant damage to the ship's hull, leading to the flooding of several watertight compartments. Despite its advanced safety features, the Titanic was unable to stay afloat, resulting in the tragic loss of over 1,500 lives.

Conclusion

The story of where Titanic was made is a testament to human ingenuity, perseverance, and the pursuit of excellence. From its origins in the bustling shipyards of Belfast to its tragic fate in the icy waters of the North Atlantic, the Titanic's legacy continues to inspire awe and admiration. By exploring the history of the Titanic's construction, we gain a deeper appreciation for the skills and dedication of the people who built it, as well as the challenges they faced in creating one of the most remarkable ships in history. The Titanic's